Getting Started with FastNesting

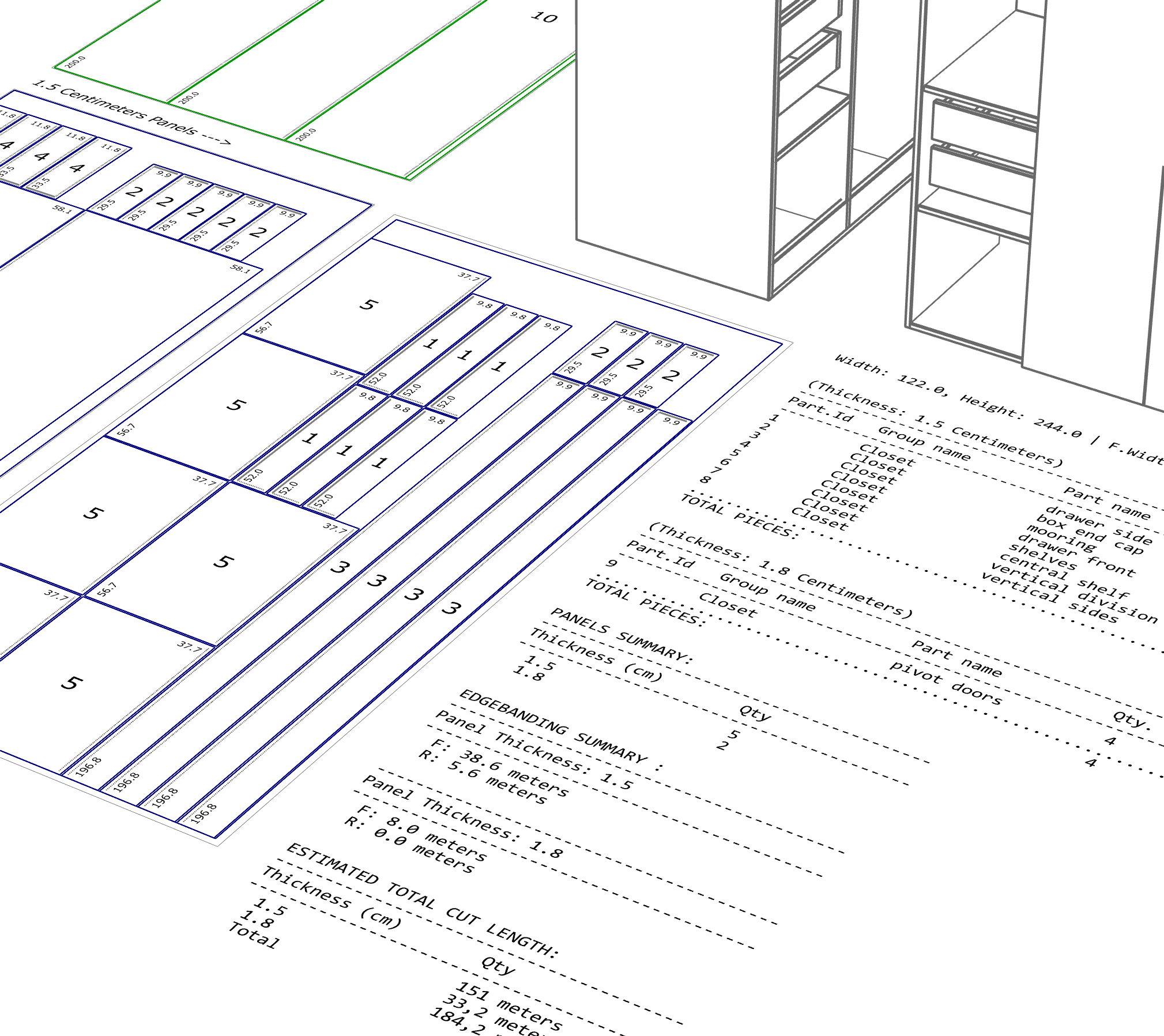

FastNesting is a powerful optimization plugin for Rhinoceros 3D that helps furniture manufacturers and CNC workshops nest pieces efficiently, from 3D model to cut list instantly.

New Features

- Report Regeneration Mode: Create reports from existing nesting layouts without re-running the algorithm

- Smart Labeling: Three labeling modes for different production needs

- Enhanced Compatibility: Optimized for Windows and macOS

- Intuitive Interface: Improved dialogs for a smoother experience

System Requirements

- • Windows: Rhinoceros 7 or 8

- • macOS: Rhinoceros 8

- • 4GB RAM minimum

- • Internet connection for license activation

License Types

All PRO Features

- Unlimited pieces

- Report regeneration mode

- Smart labeling system

- Edge banding & Excel/PDF export

5 days or 10 Rhino sessions

Basic Features

- Up to 16 pieces

- Basic nesting & Rhino reports

- No report regeneration

- No edge banding or Excel export

After trial expires

All Features Included

- Unlimited pieces (up to 8,000)

- Report regeneration mode

- Smart labeling system

- Edge banding & Excel/PDF export

Installation

FastNesting can be downloaded from Food4Rhino, our official Rhinoceros 3D plugin marketplace, from here, or installed directly within Rhino using the Package Manager.

To install via Package Manager

- Ensure you have Rhinoceros 8 installed.

- Open Rhino.

- In the command line, type

PackageManagerand press Enter. - In the search bar, type FastNesting.

- Click Install and restart Rhino if prompted.

FastNesting will start in trial mode until the trial period expires, after which it will switch to the Free version or can be activated as the Pro version.

To install from a download

If you prefer to install from a direct download instead of Package Manager, get the file from our website or Food4Rhino:

- Rhino 8 (Windows/Mac): Use Package Manager (see above), or download the

.yakfile and drag it onto the Rhino viewport. Restart Rhino if prompted. - Rhino 7 (Windows): Download the

.rhifile, close Rhino, then double-click the .rhi file to install. Reopen Rhino when done. - Mac (Rhino 8 only): FastNesting on Mac supports Rhino 8 only. Use the

.macrhior.yakfile from our website or Food4Rhino.

How to update

When a new version of FastNesting is available, choose the method that matches how you installed the plugin:

If you installed via Rhino Package Manager

Use Package Manager again to update. New versions are published to the same source (Food4Rhino).

- Open Rhino.

- Go to Tools > Package Manager (or type

PackageManagerin the command line). - Search for FastNesting, uninstall the current version if listed, then install the new version from the Package Manager.

- Restart Rhino if prompted.

If you installed from a download (.rhi, .macrhi, or .yak)

Download the new version from our website or Food4Rhino, then follow the steps for your platform:

- Rhino 8 (Windows/Mac): Use Package Manager as above, or install from a downloaded

.yakfile (e.g. drag onto the Rhino viewport). Restart Rhino if prompted. - Rhino 7 (Windows): Download the

.rhifile, close Rhino completely, then double-click the .rhi file to run the installer. Reopen Rhino when done. - Mac (Rhino 8 only): FastNesting on Mac supports Rhino 8 only. Download the

.macrhior.yakfile and install as appropriate; restart Rhino if prompted.

If you have issues (e.g. plugin not loading or duplicate install), close Rhino completely and install the new version again from our website or Food4Rhino using the same method you used originally.

Keeping your license and settings when updating

In most cases your PRO license and settings are preserved when you update: after installing the new version, open Rhino and your license should still be active.

If you have licensing problems after updating

If after updating you see license errors, "invalid license", or the plugin does not recognize your PRO license, do the following to reset and re-activate on this computer:

- In Rhino, run

License_FastNesting. - Click Deactivate License. This releases this computer from your license, so you can activate on another computer or re-activate here after reinstalling.

- If you installed via Package Manager: open Rhino, go to Tools > Package Manager, search for FastNesting, click Uninstall, then close Rhino. Otherwise, close Rhino.

- Install the new version of FastNesting (see How to update above).

- Open Rhino, run

License_FastNesting, and activate again with your same email and license key.

This process is the same on Windows and Mac. Your license key is not lost; you are only deactivating this machine so you can activate again cleanly.

User Guide

Command Reference

FastNesting

Main command to start the nesting process. Select your pieces first, then run this command. You can also select existing nesting layouts to regenerate reports without re-running the algorithm.

License_FastNesting

Activate your PRO license or view your current license status. If you already have PRO, the dialog shows your license info and a Deactivate License button. Deactivating releases this computer from your license, so you can activate on another machine or re-activate on this one after reinstalling the plugin—useful if you have licensing problems after an update.

Clean_FastNesting

Removes FastNesting metadata from selected objects (curves, panels, pieces). Use it when you want geometry to stop being treated as nesting output—for example, to reuse or export objects without FastNesting data, or to clean a layout before re-nesting.

Steps: Run the command, select one or more objects, then choose an option:

- CleanAll — Removes all FastNesting metadata (panel/piece type, dimensions, edge banding, nesting id, piece name, etc.).

- MaintainName — Same as above but keeps the piece name (

FN_Name) on each object.

The command only deletes user data (e.g. FN_*, Rotar_Pieza, Skip); it does not change the geometry.

Understanding Dialogs

System Units Dialog

Choose between Centimeters, millimeters or Inches. This will be the standard for all outputs generated during the plugin session.

Important: Ideally, set the Rhino document to "Small Objects"

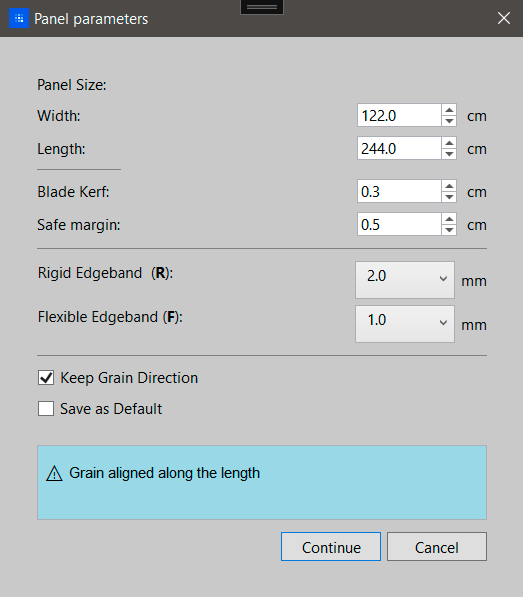

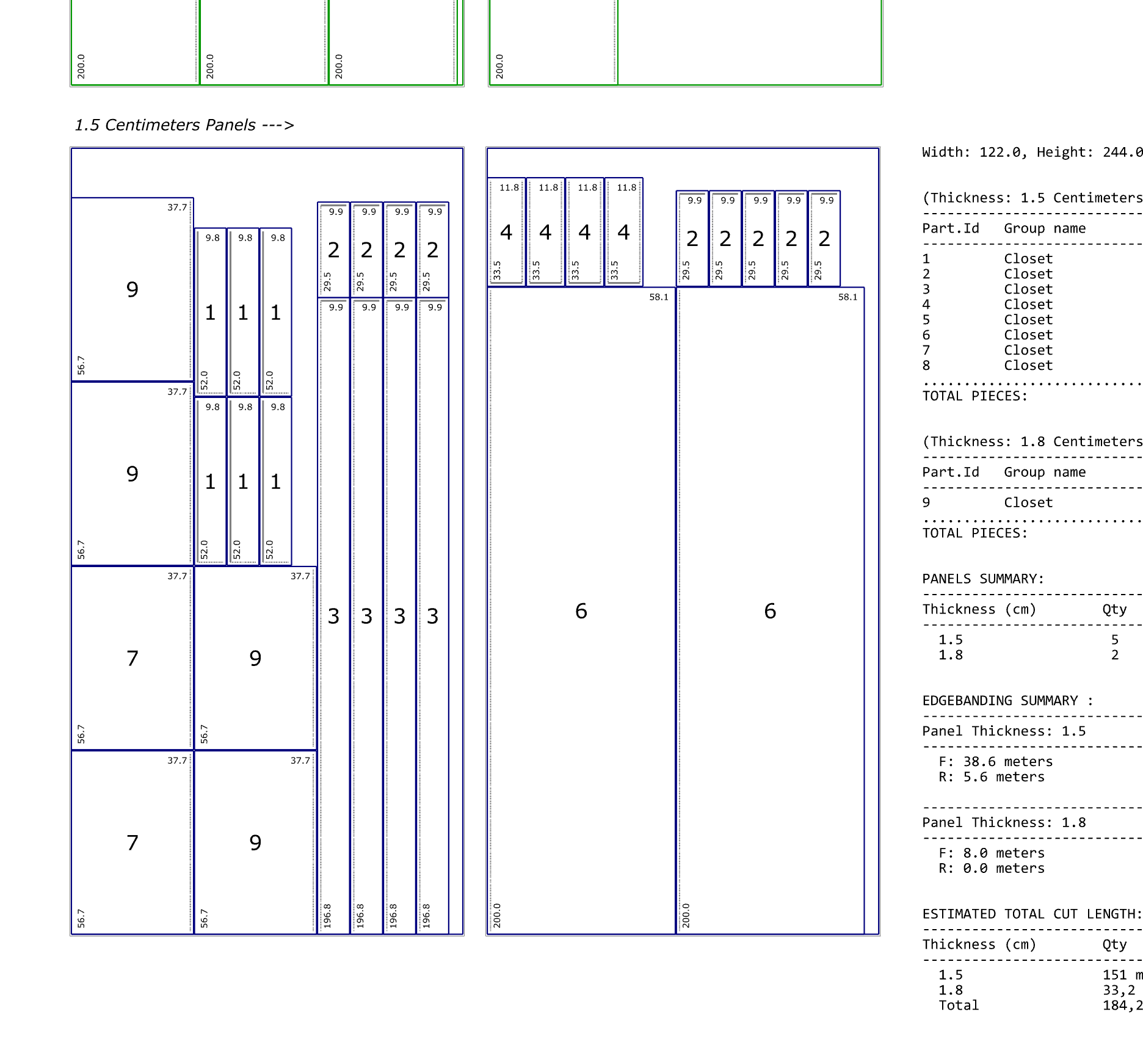

Panel Parameters Dialog

- Panel Size: Set sheet length and width — thickness is detected automatically from your Rhino model.

-

Blade Kerf: The customizable width of your cutting tool. Common values:

- 0.3 cm (3mm) Standard for most CNC router bits and thin kerf saw blades.

- 1/8" for imperial measurements: Common for full kerf saw blades.

- Safe Margin: The customizable edge margin to avoid damage. Typical: 0.5cm (5mm) or 1/4"

-

Edge Banding Thickness: Select from the most common thicknesses for your edge material.

If you plan to use edge banding, you should verify or adjust these values for the desired type R or F.

Default values:- Rigid (R): For thick edge banding (2mm) | (5/64 in)

- Flexible (F): For thin edge banding (1mm) | (3/64 in)

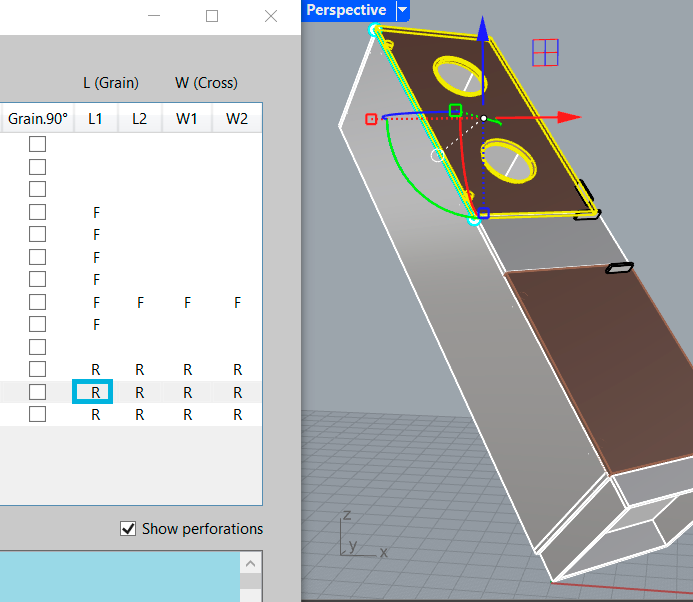

Visual representation of edge banding applied to nesting layouts.

- Keep Grain Direction: Enable when working with wood veneer to maintain grain alignment along the length.

- Save as default: Save yours personal settings (panel size, kerf, margins) for future sessions.

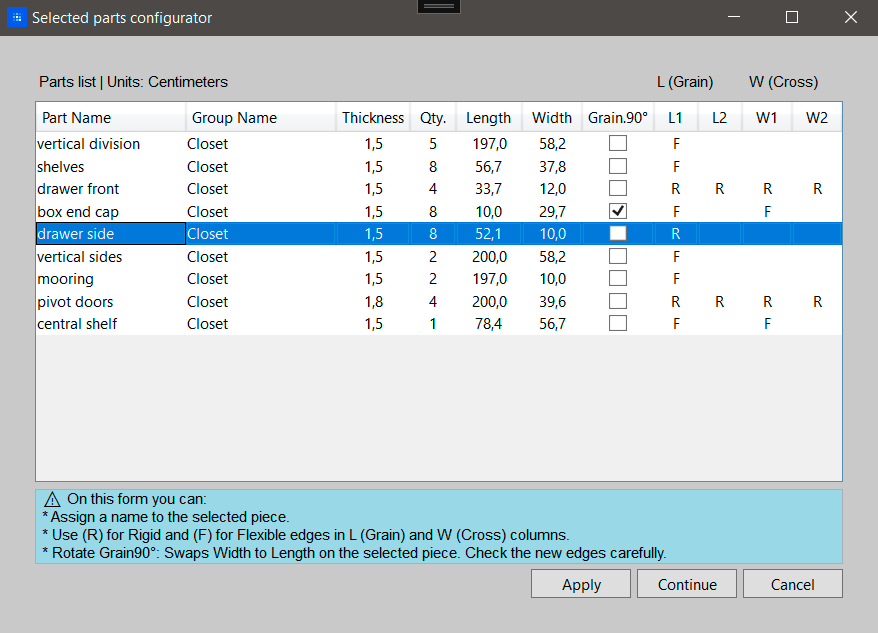

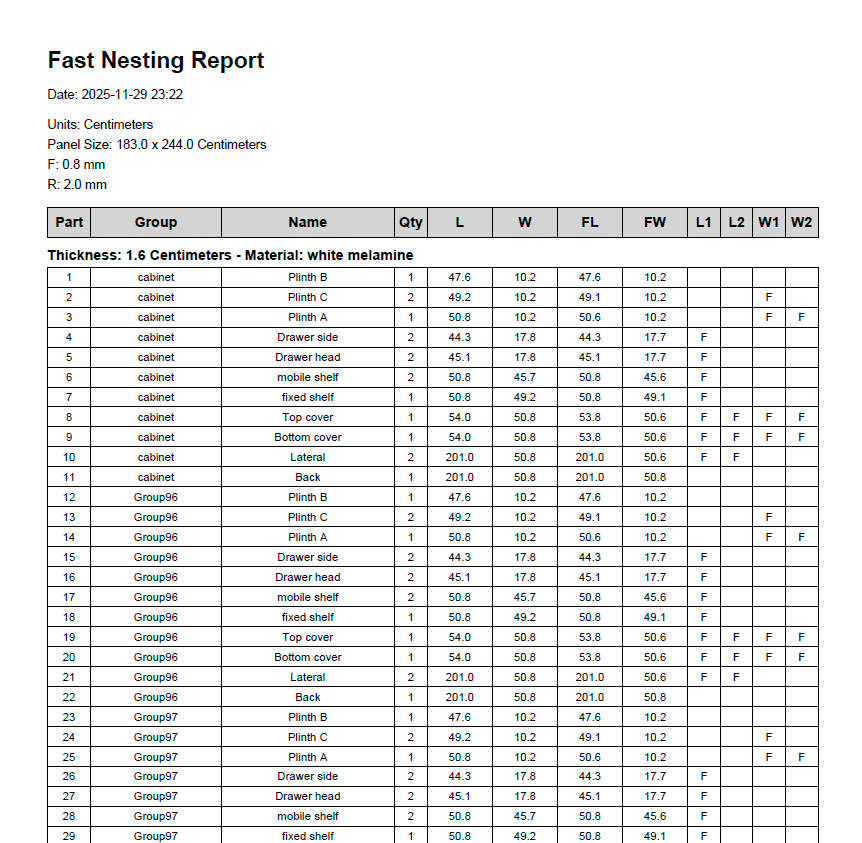

Parts Configurator Dialog

This table shows all selected pieces with their dimensions and allows you to:

- Part Name: Click to edit and give meaningful names (e.g., "Door", "Shelf", "Side Panel")

- Group Name: To see the names of the grouped parts here, you must name your part groups in Rhino before using the plugin. First, group them (command: Group) and then name them (command: SetGroupName). Examples of group names: "Closet", "Drawer", "Pantry".

-

L (Grain) & W (Cross) Columns: Set the edge banding by typing R or F:

- R = Rigid edge banding on that edge

- F = Flexible edge banding on that edge

- Empty = No edge banding

- L1, L2 = Left and Right edges along grain

- W1, W2 = Top and Bottom edges across grain

- Grain 90°: Check to rotate the grain direction for that piece

Important: Exclude parts from processing by prefixing their name with a ! (e.g., !handles). Rename the part in the Rhino modeling space for permanent exclusion, or use the ! prefix in the Part Configurator for temporary exclusion on that execution only.

Apply or Continue saves your entries to each Rhino piece. You can adjust, cancel, and resume later without issues.

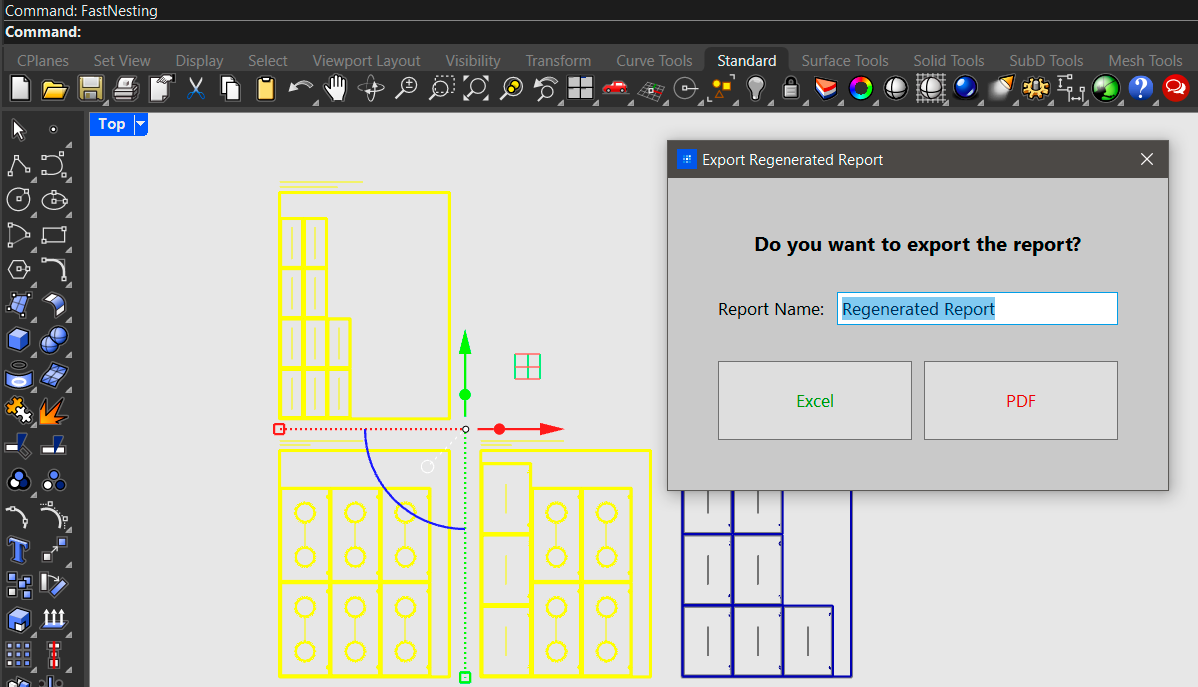

Report Regeneration Mode

Generate reports from existing nesting layouts without re-running the nesting algorithm. Perfect for when you've made manual adjustments to your pieces after the initial nesting.

How to use:

- Select pieces from an existing nesting layout in Rhino

- Run the

FastNestingcommand - Give a name to the regenerated report

- Select your desired export format (PDF or Excel)

Smart Labeling System

FastNesting offers three intelligent labeling modes to suit different production workflows:

Numbers Only

Clean, minimal labels showing only piece numbers for efficient CNC operations.

Names Only

Descriptive labels showing only piece names for easy identification during assembly.

All Information

Complete labels including numbers, names, groups, and dimensions for comprehensive documentation.

Export Options

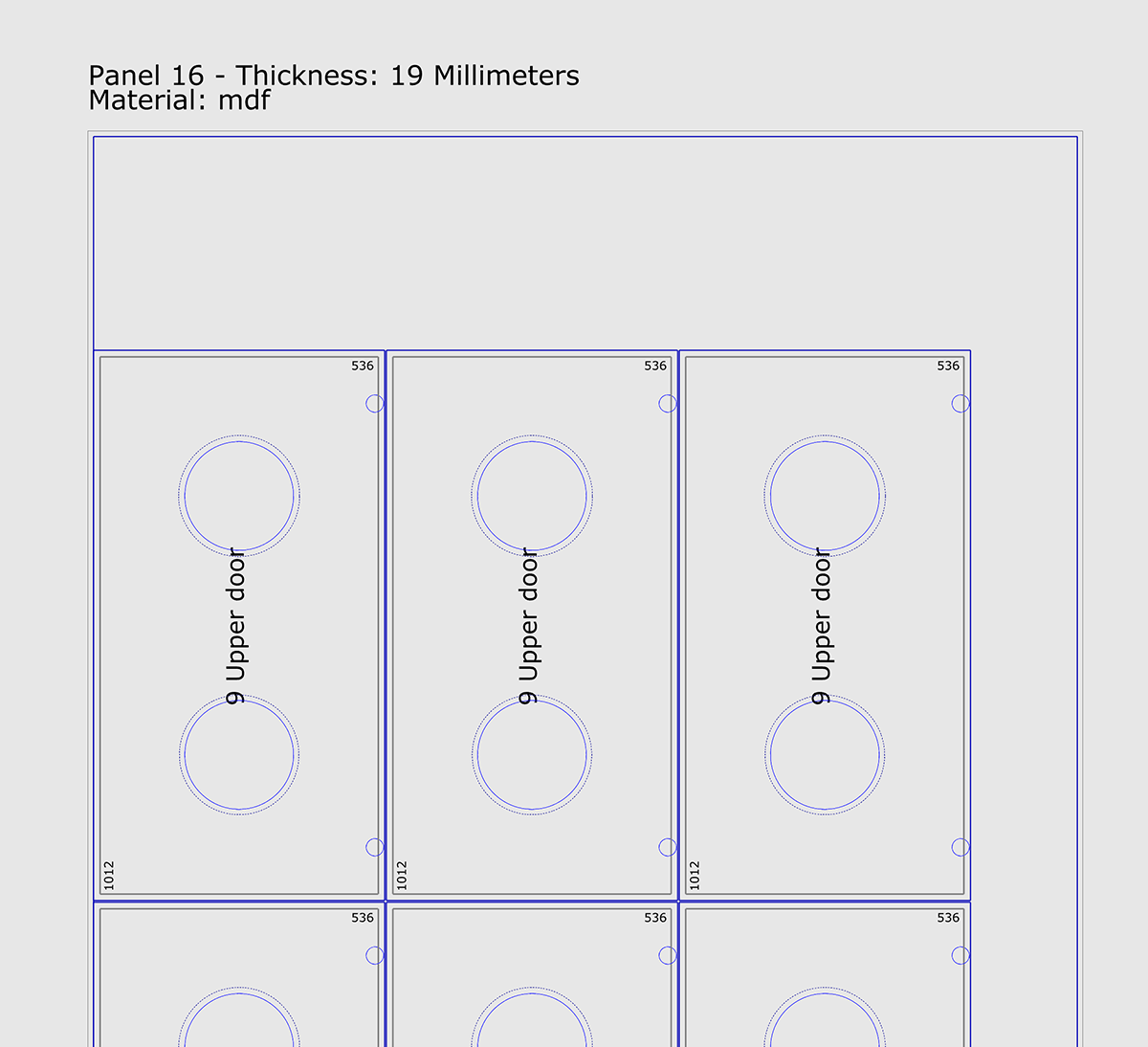

Export to Rhino Document

- Draws directly in active document

- Organized layers by function

- Smart labeling with three modes

Export your nesting results directly to your Rhino document. Perfect for CNC preparation and visual verification.

Available in: Free and PRO versions

PDF Export

- Visual layout with accurate scaling

- Detailed statistics and cut lists

- Piece labels with full information

Generate professional PDF reports with visual layouts, detailed statistics, and comprehensive piece information.

Available in: PRO version only

Excel Export

- Detailed cutting lists by material

- Separate sheets for reports and labels

- Accurate cut calculations

Export comprehensive Excel spreadsheets with detailed cutting lists, material summaries, and sticker labels for production.

Available in: PRO version only

FastNesting supports nesting with internal holes and perforations.

Best Practices

1. Name Your Pieces During Modeling

It's a good idea to name your parts when modeling in Rhino (Right panel - Properties:Object / name). Use descriptive names like "Doors," "Left_Door," "Top_Shelf," "Rear_Panel." However, you can also name each part in the Part Configurator. Remember, if you don't want a part to be considered for the process, you can name it by placing a ! before the name, for example, !handles.

2. Group and Set Group Name: Pieces by Project

Group parts by project for clear organization across sheets. Each project can include multiple sheet thicknesses, all tracked in the final report. Best Practice: Before grouping and setting the group name, it is highly recommended to select all the parts (even those already grouped) and use the Rhino command Ungroup. After confirming all parts are individual, group them again (command: Group) and apply the desired project name (command: SetGroupName). This ensures clean data and prevents errors from previous, nested groups.

3. Double-Check Your Units

Verify that the units in the System Units dialog match your Rhino model units. Mixing centimeters and inches can easily lead to confusion or incorrect scaling.

4. Set Accurate Blade Kerf

Use the real cutting width of your tool (saw or CNC). Make a test cut to determine the exact kerf, or use a slightly higher value as a tolerance.

5. Be Careful with Grain Direction

When using "Keep Grain Direction" and rotating individual pieces (Grain 90°):

- The L (Grain) and W (Cross) columns could swap

- Verify your edge banding is still correct after rotation

- Check the visual result in Rhino before exporting or printing

6. Distinguish Pieces with Unique Names

If you have multiple pieces of the same size but different edge banding, give them unique names. Otherwise, they'll be grouped together and you won't be able to distinguish them in the report.

7. Save Settings as Default

In the Panel Parameters dialog, check "Save as Default" to reuse your common settings (sheet size, kerf, margins) in future sessions.

Troubleshooting

Command "FastNesting" not found

Possible causes:

- Plugin not installed correctly

- Rhino version incompatibility (need Rhino 7 or 8)

Solutions:

- Type

PackageManagerand verify FastNesting is listed - Try reinstalling by dragging the .yak file onto Rhino

- Check Rhino version: Rhino 6 is not yet supported

License activation fails

Solutions:

- Verify you're using the same email address you used for purchase

- Copy-paste the license key to avoid typos

- Check that you have internet connection (required for activation)

- Make sure license key format is correct: XXXX-XXXX-XXXXX-XXXXXXXX

- Contact support@camonsoft.com if issue persists

Pieces don't fit on panels

What happens:

If some pieces are too large for your panel size, they won't be included in the layout. You'll see a message in the report indicating which pieces couldn't be placed.

Solutions:

- Use larger panel sizes

- Split large pieces into smaller sections in your model

- Check blade kerf and margins aren't too large

- Verify your units are correct (cm vs inches)

Measurement inconsistencies

Most common cause:

Wrong unit selection. If your Rhino model is in centimeters but you select inches in the System Units dialog, all measurements will be wrong.

Solutions:

- Check your Rhino document units: Type

Units - Select matching units in FastNesting System Units dialog

- If measurements are exactly 2.54x off, you mixed cm and inches

Edge banding errors after rotating grain

What happens:

When you rotate a piece's grain direction (Grain 90°), the L (Grain) and W (Cross) edges swap. If you don't update the edge banding settings, the wrong edges will be banded.

Solution:

- After checking "Grain 90°", review the edge banding in L and W columns

- Swap R/F values if needed to match the new orientation

- Check the visual result in Rhino before exporting

Frequently Asked Questions

How does the trial period work?

FastNesting starts in PRO trial mode from the moment you install it. The trial lasts for 5 days or 10 Rhino sessions (whichever comes first). A "session" counts each time you open Rhino and use FastNesting - you can use it multiple times within the same Rhino session without additional count.

What happens after the trial expires?

After the trial, FastNesting converts to Free version with these limitations: maximum 16 pieces per nesting, no edge banding calculation, and no Excel export. You can still generate reports in Rhino and use the plugin to measure pieces.

Can I use my license on multiple computers?

Yes! Your license grants you the flexibility to install and activate the software on up to 3 personal computers (desktop, laptop, or workstation)—giving you seamless access across your everyday devices.

Do I need internet to use FastNesting?

Internet is only required for initial license activation. After activation, FastNesting works completely offline.

Is the PRO license lifetime?

Yes! Your PRO license is lifetime for that version of FastNesting. You'll receive free updates to that version. If a major new version is released in the future, you can continue using your current version or purchase an upgrade license for the new version.

Can I get a refund?

We don't offer refunds, but you can use the 5-day PRO trial to fully test FastNesting before purchasing. This ensures you know exactly what you're buying.

Which Rhino versions are supported?

FastNesting works with Rhinoceros 7 and 8 on Windows. On Mac, only Rhinoceros 8 is supported.

Where is FastNesting available?

FastNesting is distributed exclusively through Food4Rhino, the official plugin marketplace for Rhinoceros 3D.

How many pieces can I nest in PRO version?

The PRO version allows up to 8,000 pieces. This limit was set to guarantee stable performance and accurate label exports in Excel.

Can I use FastNesting for commercial projects?

Absolutely! FastNesting PRO license includes commercial use rights. Use it for client projects, production work, and commercial manufacturing.

Does FastNesting have a toolbar?

No. FastNesting is command-based. Simply type FastNesting to start. This keeps your Rhino interface clean and works consistently across all Rhino versions.

What export formats are supported?

FastNesting can export to Rhino Document (all versions) for visual reports, PDF (PRO only) for professional layouts with statistics, and Excel (PRO only) for detailed cutting lists with accurate calculations.

What are the main improvements?

FastNesting includes several major improvements:

- Report Regeneration Mode: Create reports from existing nesting layouts without re-running calculations

- Smart Labeling: Three labeling modes (Numbers, Names, or All Information) for different production needs

- Enhanced Compatibility: Improved performance and interface optimization for both Windows and macOS

- Improved Accuracy: Better cut calculations and edge banding handling

Can I suggest new features?

Yes! We love hearing from our users. Send your feature requests to support@camonsoft.com and we'll consider them for future updates.

Need More Help?

Can't find what you're looking for? Our support team is here to help you get the most out of FastNesting.